At Morris Leslie Plant Sales, we pride ourselves on offering customers more than just machinery, we offer reliability. That’s why every machine that transitions from our hire fleet into our sales yard goes through a carefully managed reconditioning process. Each step is designed to ensure the machine not only looks its best but works like new.

Here’s how our team prepares used machines for their next owner.

Step 1: Arrival and Initial Assessment

Team Involved: Yard Manager & Inspection Staff

Location: Hire Depot Receiving Area

Once a machine finishes its time in our hire fleet, it’s transported from the depot to our main site. On arrival, it undergoes a 360° visual inspection. This includes:

- Checking tyre conditions

- Inspecting for rust or corrosion

- Identifying any paint chips or cosmetic damage

- Reviewing the cab condition and visibility features (mirrors, windows, etc.)

We also take note of key details like the serial number, hours used, and overall working condition, all logged using an internal inspection sheet.

Step 2: Deep Cleaning

Team Involved: Yard Operatives

Location: Wash Bay

Before any further assessment or repairs, the machine heads to our dedicated wash bay. Here it receives a full external and cab clean using high-pressure hoses and degreasers to remove mud, oil, and build-up from months on site.

A clean machine helps us better spot any hidden damage or wear, especially around joints, seals, and undercarriage components.

Step 3: Mechanical Service & Repairs

Team Involved: Workshop Technicians

Location: On-site Service Workshop

Now it’s time for the real performance check. Our workshop team conducts a full service, including:

- Fluid and filter changes

- Greasing moving parts

- Checking hydraulics

- Testing controls and engine performance

Any faults picked up are repaired immediately using on-site parts where possible. This ensures the machine doesn’t just look good, it’s in top operational condition.

Step 4: Cosmetic Refurbishment

Team Involved: On-site Painter & Detailers

Location: Paint Bay

After servicing, the machine enters our paint bay where the cosmetic revival begins. Our on-site painter carefully masks off key areas and re-sprays damaged panels or full bodies, depending on condition.

We also:

- Replace stickers/decals

- Restore branding and safety signs

- Fit new tyres if needed (kept on-site for quick turnaround)

This step often makes the biggest visual difference, turning a used machine into something showroom worthy.

Step 5: Final Quality Check & Documentation

Team Involved: Yard Supervisor & Sales Coordinator

Location: Pre-Sales Area

Once cosmetic and mechanical work is complete, a final quality control check is carried out. This ensures:

- All features are operational

- Appearance meets our sales standard

- Documentation (hours, ID plate, spec) is accurate

Details are recorded and passed to the sales team. The machine is then moved to our sales lot, where it’s positioned, photographed, and prepared for listing.

Step 6: Online Listing & Sales Ready

Team Involved: Marketing & Sales Team

Location: Office & Sales Yard

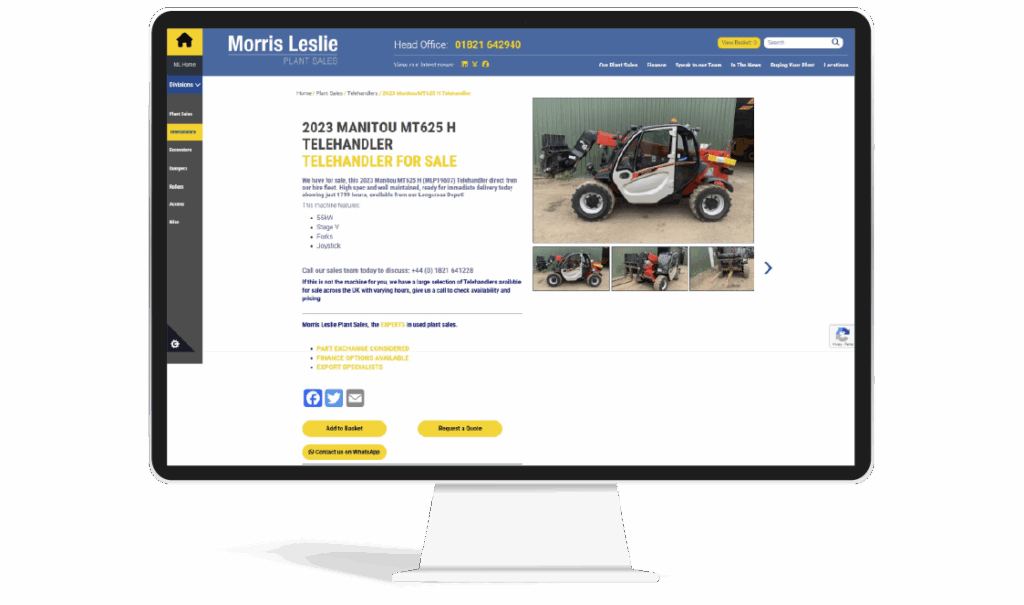

The final step is uploading the machine to our website. Using high-quality photos and verified specs, we ensure each listing reflects the true condition and value of the unit.

Because we’ve handled the reconditioning in-house, we can confidently say: this machine is ready to go to work for its next owner, with no surprises.

Timeframe & Efficiency

Thanks to our on-site parts, paint, tyres, and technicians, the entire process can be completed within a few weeks, often faster for priority units.

Why It Matters

This reconditioning process doesn’t just increase resale value – it gives our buyers confidence. Whether they’re purchasing an excavator or a telehandler, they know it’s been treated with care, backed by a team that understands what “good as new” really means.

View our fleet and buy with confidence at Morris Leslie Plant Sales or contact our sales representatives by emailing [email protected] or calling 01821 642 940